5050RGB全彩内置IC

5050RGB内置IC幻彩灯珠 HKA5812全彩LED内置IC 5050内置IC智能RGB七彩LED

1. 产品特性:(Features)

Ø 垂直型表贴P4脚位封装: vertical table stick P4 feet a package

Ø 防潮等级:2a: Moisture proof level: 2a:

Ø 5.0长*5.0宽*0.7高 : (L)5.0 *( W)5.0 * (H)0.7

Ø 宽发光角度:2θ1/2=120: Wide light Angle: 2 1/2 = 120 theta

Ø 包装:1000颗/卷: Packaging: 1000 / volume:

Ø 内部集成高质量串行级联恒流IC:

Internal serial cascade constant current IC integrated quality

Ø 三路恒流驱动:Three-way constant current driver

2. 应用:(Applications )

Ø LED全彩模组:LED full-color module

Ø LED全彩发光字灯串: LED full-color module

Ø LED幻彩软硬灯条:LED super soft article lamp

Ø LED护栏管:LED guardrail tube

Ø LED点光源,LED像素屏:LED light source, LED pixel screen

Ø LED异形屏:LED abnormity screen

Ø LED跑马灯条:LED running lights

Ø 汽车辅助照明:car auxiliary lighting:

Ø 其他适合的应用: other suitable applications

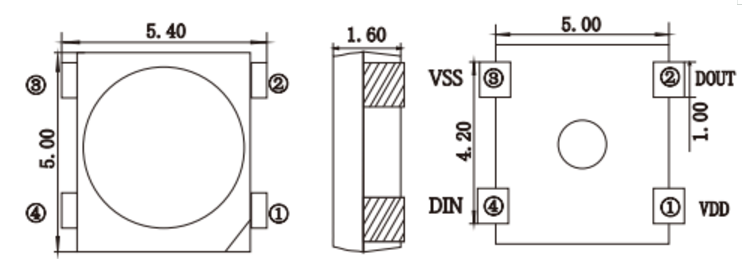

3. 尺寸图 (Outline Dimensions)

封装尺寸:Package Dimensions

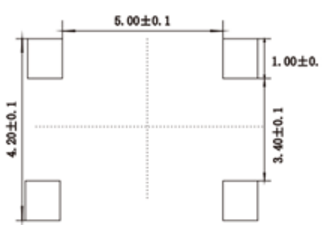

建议焊盘尺寸图

备注:(Notes:)

*所有标注尺寸单位为毫米: All dimension units are millimeters.

*除特别标注外,所有尺寸允许公差±0.1mm : All dimension tolerance is ±0.1mm unless otherwise not.

4. 产品对应管脚功能说明

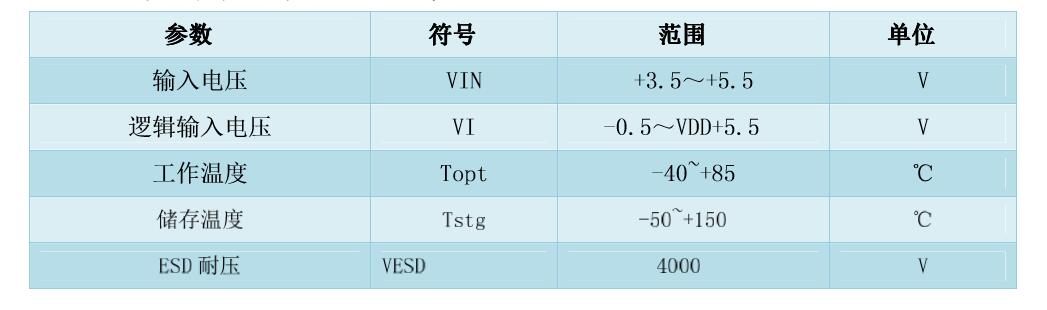

5. 电气参数(极限参数,Ta=25℃,VSS=0V)

6. 电气参数(Ta=25℃,Ta=-20~VSS=0V)

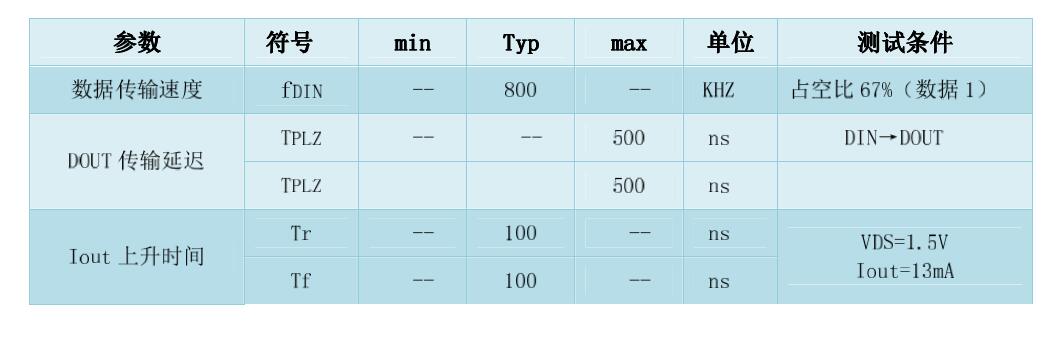

7. 动态参数:(Ta=25℃)

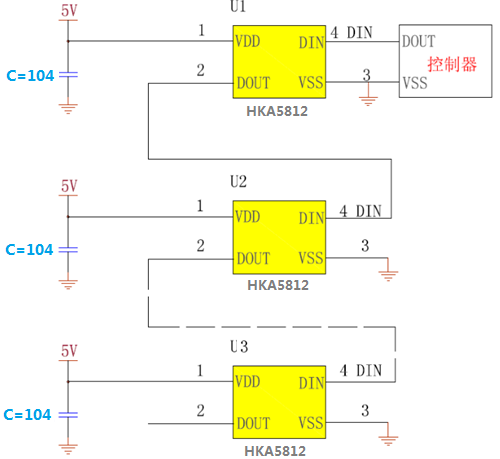

典型应用电路:()

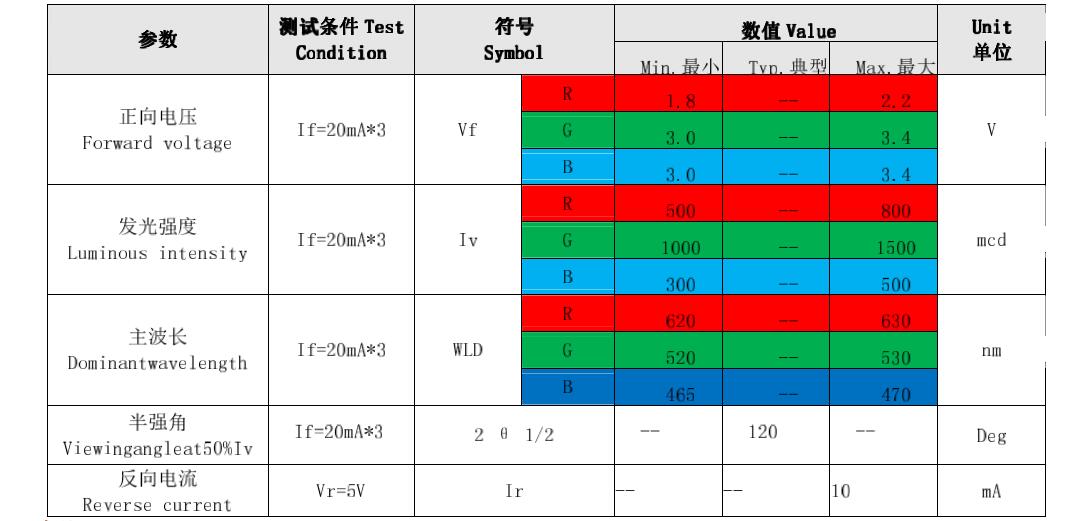

8. 光电参数(温度=25℃):(Electrical-Optical Characteristics)

备注[Note]:

*光通量(LM)±10% Luminous intensity(LM) 10%

*正向电压±0.05 Forward Voltage (VF)0.05V

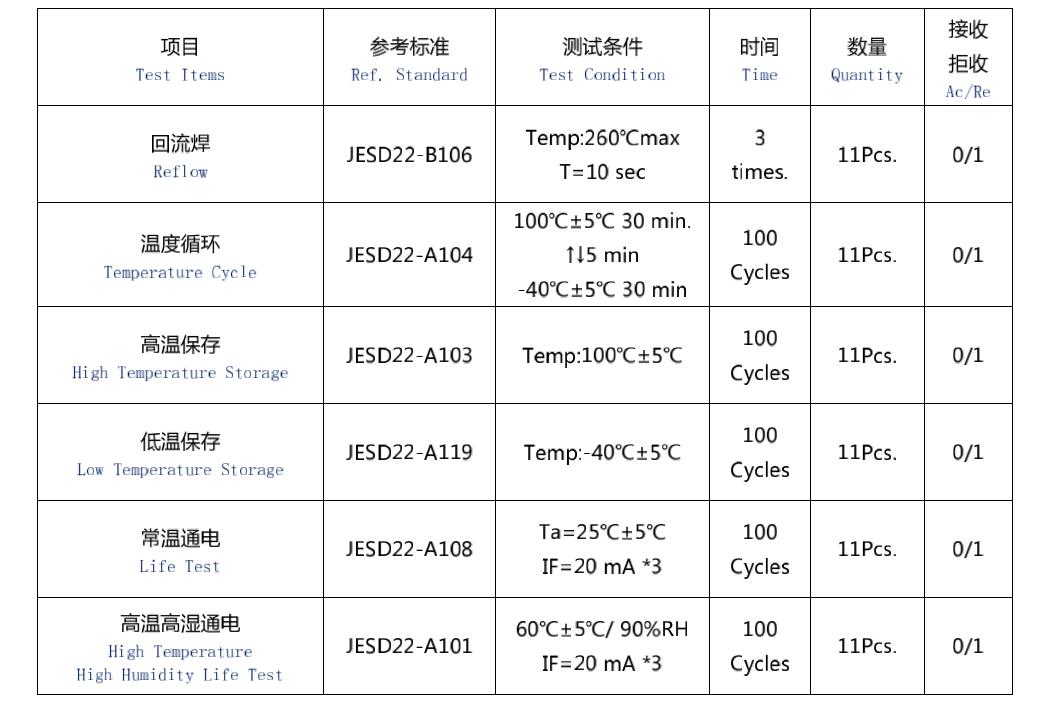

9.信赖性测试项目及标准:Test items and results of reliability

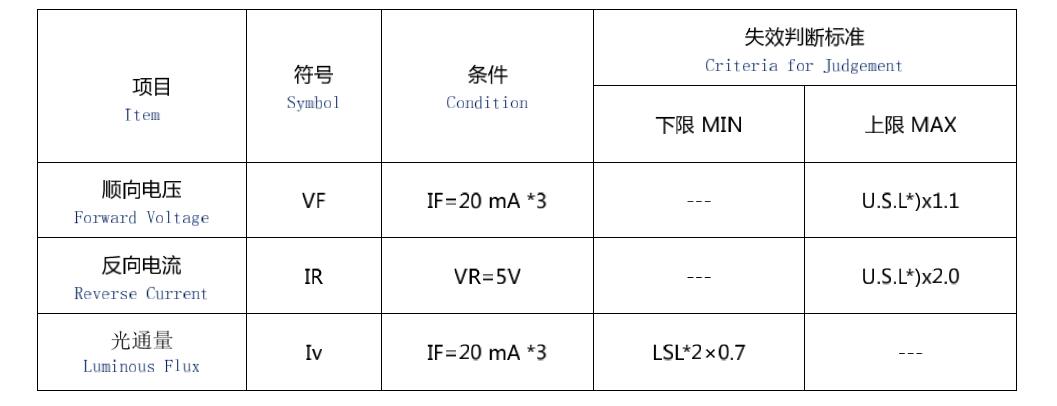

10.失效判断标准:Criteria for judging the Damage

备注:[Note]:*USL:标准上限值U.S.L: Upper standard level *LSL:标准下限值 Lower Specification Level

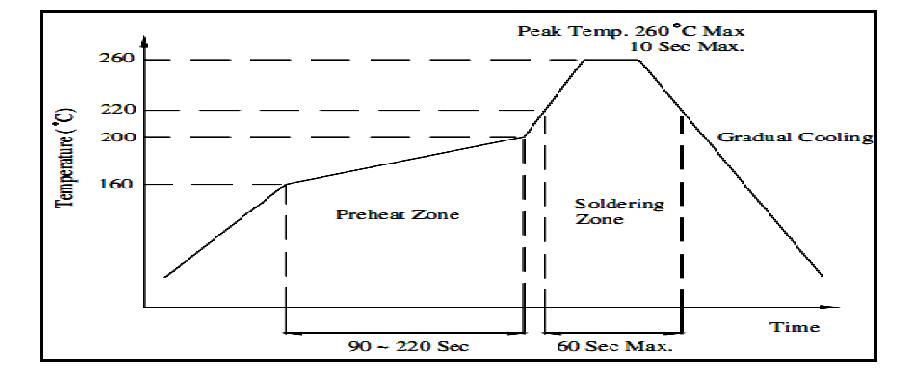

11.回流焊接曲线图:IR reflow soldering Profile

注意:NOTES

Ø 我们建议的回流焊温度为240℃±5℃,最高的焊接温度要控制在260℃以内。

We reeommend the reflow temperature 240℃±5℃.the maximum soldering temperature should be limited to 260°

Ø 当产品在处在高温状态中时不要对其硅胶施加压力。

Don’t cause stress to the silicone resin while it is exposed to high temperature.

Ø 回流焊的次数应小于两次。

Number of reflow process shall be 1 time.

Ø 灯珠不要焊接在弯曲的PCB板上,焊接之后,也不要弯折线路板。

Components should not be mounted on warped (non coplanar) portion of PCB. After soldering, do not warp the circuit board.LED

Ø 回流焊之后冷却过程中,不要对材料实加外力,也不要有震动,回流焊后,不要采用激剧冷却的方式。

Do not apply mechanical force or excess vibration during the cooling process to normal temperature after soldering.Do not rapidly cool device after soldering.

Ø LED工作环境及与LED适配的材料中硫元素及化合物成份不可超过100PPM

LED operating environment and sulfur element composition cannot be over 100PPM in the LED mating usage material.

Ø 当我们需要使用外封胶涂抹LED产品时,应确保外封胶与LED封装胶水相匹配,因为大多数LED的封装胶水为硅胶,它有较 强的氧化性和较强的吸湿性,必须防止外封材质进入LED内部以造成LED的损伤,单一的溴元素含量要求小于900PPM,单 一氯元素含量要求小于900PPM,在涂抹LED产品时要求外封胶溴元素与氯元素总含量必须小于1500PPM

When we need to use external glue for LED application products, please make sure that the external glue matches the LED packaging glue. Additionally ,as most of LED packaging glue is silica gel, and it has strong Oxygen permeability as well as strong moisture permeability; in order to prevent external material from getting into the inside of LED, which may cause the malfunction of LED, the single content of Bromine element is required to be less than 900PPM,the single content of Chlorine element is required to be less than 900PPM,the total content of Bromine element and Chlorine element in the external glue of the application products is required to be less than 1500PPM.

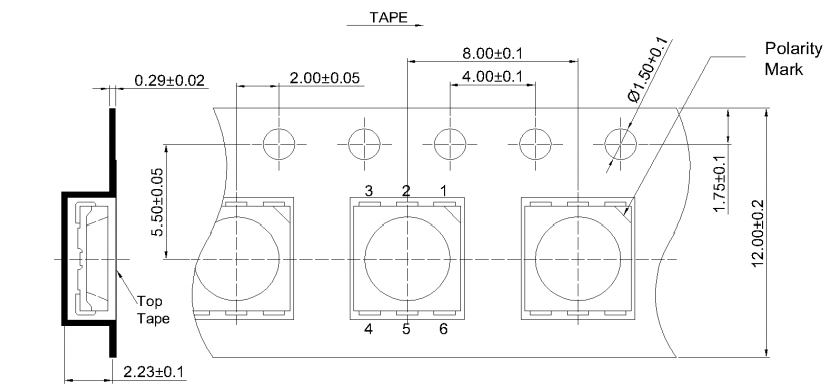

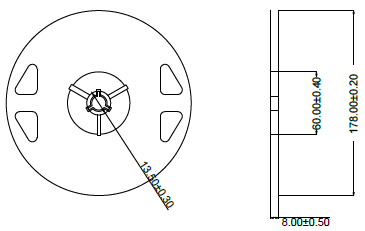

12.包装规格 :Packing specification

Ø 标签:(Label): /

Ø 载带规格(单位:mm):Tape Specifications (Units : mm)

Ø 卷轴尺寸:Reel Dimensions

Ø 防潮带包装:(Moisture Resistant Packaging )

注:标注公差为±0.1mm ,单位:mm :(Note: The tolerances unless mentioned is ±0.1mm , Unit: mm )